Liquid Cylinders 450 Dewar

- Different volume and pressure levels are available to meet a variety of needs

- It is an ideal container for storing cryogenic liquids such as liquid oxygen, liquid nitrogen, liquid argon, liquid carbon dioxide, nitrous oxide, and liquefied natural gas.

- Improve your market party's competitiveness by using safer and more cost-effective advantages than using ordinary gas cylinders.

- the unique structural design and special insulation technology, and the use of all imported insulation materials, make the product insulation performance is excellent.

- With a buoyant visual level gauge, the quality is stable

- Both inner and outer gallbladders are made of austenitic stainless steel to provide a durable and durable structure.

- The outer simplified body is made of thick stainless-steel plate and has strong impact resistance.

- The outer casing-stainless steel is polished.

Description

Reviews

Liquid Cylinders 450 Dewar

DPL series welding insulated gas cylinders are designed, manufactured, inspected and accepted according toGB24159-2009 0r QDP0103-2014.

Product Introduction:

DPL series welding insulated gas cylinders are designed, manufactured, inspected and accepted according to GB24159-2009 or QDP01032014. They are used for deep liquids such as liquid oxygen, liquid nitrogen, liquid hydrogen, liquid carbon dioxide, oxidized sub-alloy and LNG. lt is fast, convenient and economical.

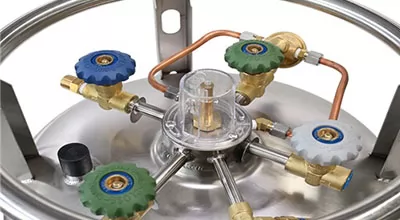

DPL series welded thermal insulation cylinders are made of high quality imported thermal insulation material, unique vacuum insulation technology, excellent thermal insulation performance, long storage time, very low evaporation rate, high gas discharge flow rate, optima Life cycle cost. The DPL series welded insulated cylinders are modular in design, with volumes ranging from 160L to500L, and working pressures are divided into 3 levels, medium pressure series (working pressure 1.38MPa, labeled Mpa), high pressure series (workingpressure2.4MPa), marked as HP), ultra-high pressure series (working pressure is 3.5lMPa, marked as VHP), customers can choose the best according to the use. The pipelines and valves of DPL series welded thermal cylinders are integrated design, easy to use and maintain, easy to operate and safe to use. DPL series welded insulated cylinder liner and outer casing are made of austenitic stainless steel, rubber shock ring base, strong impact resistance, durable, stable and reliable.

Product Characteristics

Different volume and pressure levels are available to meet a variety of needs

It is an ideal container for storing cryogenic liquids such as liquid oxygen, liquid nitrogen, liquid argon, liquid carbon dioxide, nitrous oxide, and liquefied natural gas.

Improve your market party's competitiveness by using safer and more cost-effective advantages than using ordinary gas cylinders.

the unique structural design and special insulation technology, and the use of all imported insulation materials, make the product insulation performance is excellent.

With a buoyant visual level gauge, the quality is stable

Both inner and outer gallbladders are made of austenitic stainless steel to provide a durable and durable structure.

The outer simplified body is made of thick stainless-steel plate and has strong impact resistance.

The outer casing-stainless steel is polished.

With imported valve configuration, the reliability is stronger. The integrated pressure control combination regulator has the function of self-pressurizing control valve and economic valve, which is very convenient to use.

The exterior of the bottle has a complete information display system, providing a full range of safe operation guidelines.

The high-strength spray rust-proof frame can meet the different requirements of lifting and forklift movement.

Vertical and horizontal cryogenic cylinders are available upon request.

Technical Specification