Controlled Rate Liquid Nitrogen Freezers BD Series

- Dual solenoid valves design, one for working, the other for backup. When one valve fails, switch to the other valve through touch screen controller

- Consistent temperature control and uniformity achieved via an air-handling system and liquid nitrogen injection

- Environmentally friendly insulating foam

- Type 304 stainless steel with exterior powder-coat finish

Description

Reviews

Controlled Rate Freezer BD Series

Innovative technology for reproducible result and highest sample viability.In order to maintain cellular viability during the freezing process, certain cells – such as protist, mammalian, and plant cells – require precise control of the freezing rate in order to minimize the detrimental effects of undercooling and the heat liberated during the phase change process from water to ice.

Controlled rate freezing is an established procedure for the cryopreservation of biologic material in research and clinical applications. In-line with GMP protocols, cell material can be frozen then stored at cryogenic temperatures.

BD series controlled-rate freezer (CRF) achieve reliable, reproducible results with maximum operational safety. They are used for clinical, veterinary and research tasks for controlled rate freezing of samples.

Dependable sample protection

For customers in research, cell and gene therapy, vaccine production, and biobanking, the CryoVita CRF provides precise, repeatable freezing results that protect the sample from intracellular freezing.

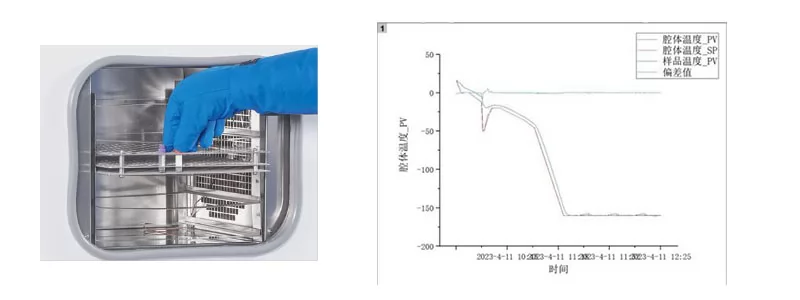

Liquid nitrogen flows via a metal hose connection, as a gas, into the freezing chamber.predetermined cooling profiles are used to freeze samples prior to removal and storage at cryogenic temperatures. Data logging ensures continual monitoring of the entire process, including multiple temperature sensor set-points, actual values and the supply pressure of liquid nitrogen.

Reliable temperature performance for high-throughput usage

Dual solenoid valves design, one for working, the other for backup. When one valve fails, switch to the other valve through touch screen controller

Consistent temperature control and uniformity achieved via an air-handling system and liquid nitrogen injection

device

Environmentally friendly insulating foam

Type 304 stainless steel with exterior powder-coat finish

User-friendly operation with enhanced data traceability

Intuitive touchscreen display allows for easy set-up, operation, and review of a freezing run

Six pre-set freezing profiles and space for up to 20 user-defined, “custom” freeze profiles

Convenient to create and edit a custom program on touch screen

Record temperature curve of each cycle automatically

External influences are avoided during freezing

Real-time run monitoring for sample protection

Chamber and sample temperatures are monitored by Type T thermocouples, eliminating lag time and providing

“real time” responsiveness

Standard alarms to alert users of thermocouple failures, heater malfunction, high/low temperature limits,

temperature tracking, power failure, and completion of run

RS232 Port

USB port to download running data

Installation

YDZ series self-pressurized liquid nitrogen

Container is recommended to supply liquid nitrogen

BD series controlled rate freezers.

0.1MPa pressure

Pressure building regulator

Liquid level meter (float type/ electric digital type)

Casters for easy movement

Freezing Racks and Rack Holders

Specifications (Horizontal)